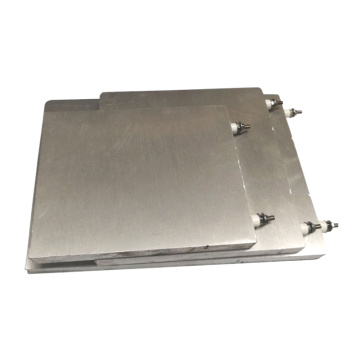

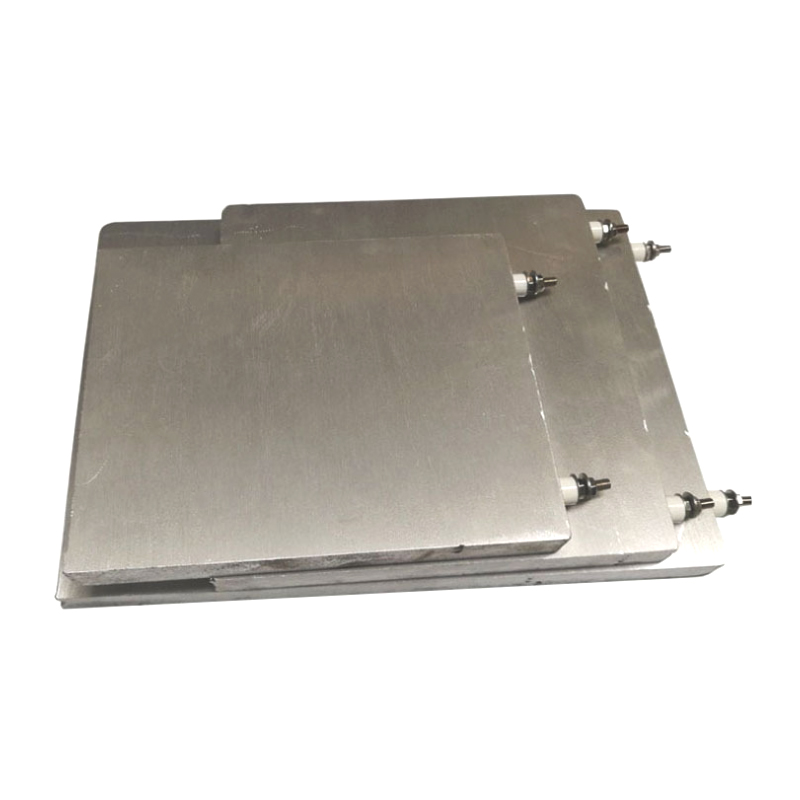

Custom Aluminium Cast Heating Plate

Product Description

Company Profile

Cast aluminum electric heating plate is a kind of metal casting heater, which takes tubular electric heating element as heating body, and is bent into shape. It enters the mold with high-quality metal alloy material as shell, and is centrifugally cast into various shapes, including round, flat, right angle, air-cooled, water-cooled and other special shapes. The surface load of cast aluminum can reach 2.5-4.5 w / cm2, and the working temperature can reach about 350 ℃; The surface load of cast copper can reach 3.5-5.0w/cm2, and the working temperature can reach about 600 ℃; The surface load of cast iron can reach 4.5-6.0w/cm2 and the working temperature can reach 600 ℃. The metal casting heater is a kind of heater with high efficiency and uniform heat distribution. The metal alloy with good thermal conductivity ensures the uniform temperature of the hot surface and eliminates the hot and cold points of the equipment. It has the advantages of long life, good thermal insulation performance, strong mechanical performance, corrosion resistance and magnetic field resistance. The heat preservation device is added on the outer heat dissipation surface, and the infrared ray is sintered on the inner heat dissipation surface, which can save 35% of electricity.

size | customized | effect | heating |

1. The working voltage shall not exceed 10% of the rated value; The relative humidity of air shall not be more than 95%, and there shall be no explosive and corrosive gas. 2. The wiring part is placed outside the heating layer and insulation layer, and the shell shall be effectively grounded; Avoid contact with corrosive, explosive media and water content; The lead wire shall be able to bear the temperature and heating load of the wiring part for a long time. When the connection screws are tightened, excessive force shall be avoided. 3. The metal casting heater shall be placed in the dry place. If it is placed for a long time, the insulation resistance shall be less than 1m Ω When, can bake in the oven of about 200 ℃ for 5-6 hours, and then it can return to normal. Or reduce the voltage to power up the heating until the insulation resistance is restored. 4. Metal casting heater shall be positioned and fixed, and effective heating area must be closely connected with the heat receiver, and no empty burning is allowed. If dust or pollutants are found on the surface, it should be cleaned and reused in time to avoid heat dissipation and shorten the service life. 5. The magnesia powder at the outlet of the electric heating pipe shall be prevented from being infiltrated by pollutants and water in the use place, and the leakage accident shall be prevented.

Details Images

Product Categories : Application accessories > Application accessories

Other Products

Hot Products

Hyd-14 Type High Holding Power Anchor Hhp AnchorPet Polyester Braid Rope for Towing and MooringWater Reducer for Concrete and Mortar in Construction IndustryCk Chain Hoist Heavy Duty Chain BlockUs Type Aluminium Oval SleevesG-411 Us Type Commercial ThimblesSs304 7*7 S. S Wire RopeBlack Painted Marine Studless Anchor ChainHigh Quality Galvanized DIN741 Wire Rope ClipsG80 Rachet Load Binder with HooksG100 Clevis Sling Hook with LatchNew Danforth High Holding Power Boat AnchorDIN1480 Wire Rope Turnbuckle for ConnectingEye Screw DIN 580 (M6-M64)Us Type Galvanized G2130 Bow ShackleHigh Quality Galvanized Iron Short Link Chain